Web Menu

Product Search

Exit Menu

Are there differences in Bow-type Drop fiber optic cable for indoor versus outdoor applications?

Are there differences in Bow-type Drop fiber optic cable for indoor versus outdoor applications?

Bow-type Drop fiber optic cable has become a critical component in modern telecommunications infrastructure, particularly in residential and commercial fiber networks. These cables are designed to provide high-performance, reliable fiber connections for a range of deployment scenarios.

Structural differences in Bow-type Drop fiber optic cable

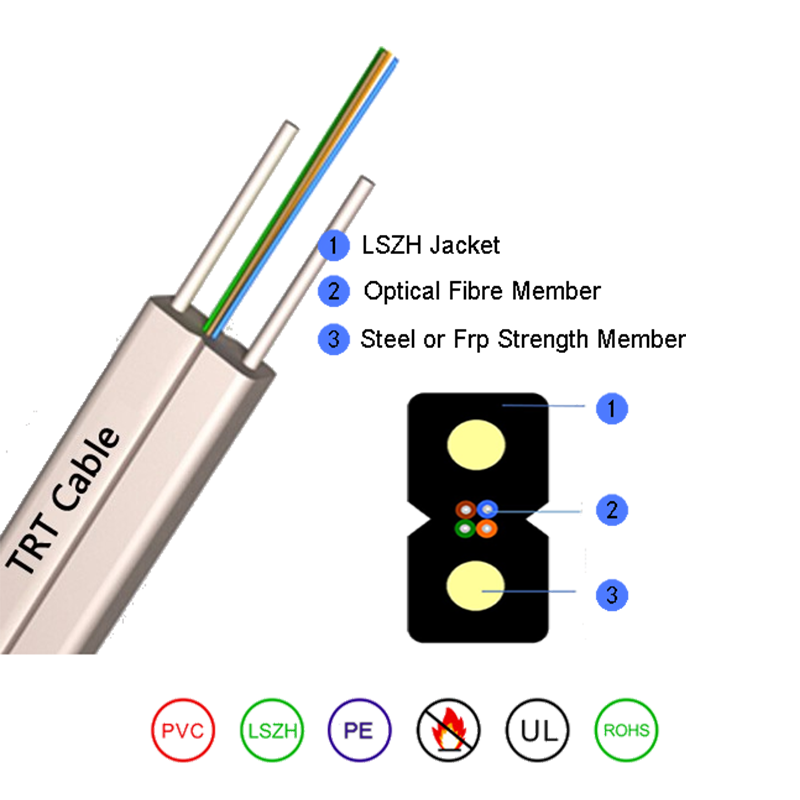

One of the primary differences between indoor and outdoor Bow-type Drop fiber optic cable lies in their cable construction and materials. Indoor cables are generally designed for environments that are climate-controlled, clean, and free of physical hazards. They typically feature a flexible, tight-buffered design, which allows for easy handling, routing, and termination within buildings. The jacket material of indoor Bow-type Drop fiber optic cable is usually PVC or other low-smoke, flame-retardant compounds to meet building codes and ensure safety in case of fire.

In contrast, outdoor Bow-type Drop fiber optic cable must withstand harsher environmental conditions, including temperature fluctuations, UV exposure, moisture, and mechanical stress. Outdoor cables often feature a loose-tube design with water-blocking compounds to prevent moisture ingress, as well as a more robust outer jacket made of polyethylene (PE) or UV-resistant materials. This design ensures long-term durability when cables are installed aerially, underground, or in conduit systems.

Additionally, outdoor Bow-type Drop fiber optic cable may include reinforcement elements such as armored layers or dielectric strength members to resist rodent damage and tensile stress during installation and service life. These elements are typically unnecessary in indoor applications, where the risk of mechanical damage is lower.

Performance considerations

Performance characteristics differ between indoor and outdoor Bow-type Drop fiber optic cable due to variations in design and environmental exposure. Indoor cables prioritize flexibility, ease of installation, and tight bend radius, which are crucial for routing cables through ceilings, walls, and conduits in dense building layouts. Tight-buffered fibers allow for direct termination on connectors without the need for additional protection, making indoor cables suitable for high-density applications such as fiber-to-the-home (FTTH) deployments, office networks, and server rooms.

Outdoor Bow-type Drop fiber optic cable, on the other hand, emphasizes signal integrity and environmental protection over flexibility. Loose-tube construction isolates fibers from external stress, reducing microbending and attenuation that could compromise signal quality. Outdoor cables are also engineered to maintain performance across a wide temperature range, ensuring that fiber connections remain stable even in extreme climates. For areas with potential flooding or high moisture levels, water-blocking materials in the cable core prevent degradation of the optical fibers.

It is worth noting that some Bow-type Drop fiber optic cable designs are suitable for both indoor and outdoor applications, often referred to as “dual-rated” cables. These cables combine a flexible inner structure for easy indoor handling with robust outer protection for outdoor deployment.

Installation considerations

The installation environment significantly impacts the choice of Bow-type Drop fiber optic cable. Indoor installation requires cables that are easy to route, terminate, and manage. Installers often work within limited space and around building infrastructure, so lightweight and flexible cables are preferred. Flame-retardant properties and compliance with building safety standards are critical when installing indoor Bow-type Drop fiber optic cable in populated areas.

Outdoor installation presents different challenges. Bow-type Drop fiber optic cable must be resistant to physical damage, UV exposure, and environmental stresses. Installation methods may include aerial suspension on poles, direct burial, or conduit placement. Outdoor cables often require specialized tools and techniques to maintain proper tension, bending radius, and protection during deployment. Additionally, temperature fluctuations during installation must be considered, as outdoor Bow-type Drop fiber optic cable can expand and contract with thermal changes, potentially affecting performance if not managed properly.

Environmental resistance

Environmental resistance is a key differentiator between indoor and outdoor Bow-type Drop fiber optic cable. Indoor cables operate in controlled environments with minimal exposure to water, sunlight, or extreme temperatures. Therefore, indoor cables can prioritize flexibility and ease of handling over environmental robustness.

Outdoor Bow-type Drop fiber optic cable is designed for harsh environments, including prolonged exposure to UV radiation, heavy rainfall, snow, and extreme temperatures. These cables incorporate UV-resistant jackets, water-blocking gel or tapes, and sometimes armor layers to ensure the fiber core remains protected over decades. In regions with significant rodent activity, outdoor cables may include metal or dielectric reinforcement to prevent bite-through damage. Selecting outdoor-rated Bow-type Drop fiber optic cable ensures long-term reliability and reduces maintenance costs in challenging environments.

Compliance and safety standards

Compliance with industry standards is critical for both indoor and outdoor Bow-type Drop fiber optic cable, though the requirements differ. Indoor cables must meet building codes and fire safety standards, including low-smoke, zero-halogen (LSZH) or flame-retardant PVC ratings. These standards ensure safe installation in populated areas, minimizing hazards in case of fire.

Outdoor cables adhere to standards for environmental resistance and mechanical durability. This includes UV resistance, tensile strength ratings, water-blocking capabilities, and temperature operating ranges. In some regions, outdoor cables must also meet specific telecommunications regulatory requirements, ensuring that they are suitable for long-term deployment in public or utility infrastructures. Buyers should verify that the Bow-type Drop fiber optic cable they select meets the relevant indoor or outdoor standards for their project.

Cost considerations

Cost differences between indoor and outdoor Bow-type Drop fiber optic cable primarily reflect material and design requirements. Indoor cables are generally less expensive due to their simpler construction and absence of protective layers. Their lightweight and flexible design reduces installation complexity, further lowering total deployment costs.

Outdoor Bow-type Drop fiber optic cable is typically more costly because of robust jackets, water-blocking elements, and reinforcement features. However, these additional costs are justified by the cable’s durability, long service life, and reduced maintenance requirements. When planning a network, it is important to balance upfront costs with long-term performance, considering both indoor and outdoor cable requirements.

| Feature | Indoor Bow-type Drop fiber optic cable | Outdoor Bow-type Drop fiber optic cable |

|---|---|---|

| Jacket material | PVC, LSZH | PE, UV-resistant |

| Fiber protection | Tight-buffered | Loose-tube with water-blocking |

| Mechanical protection | Minimal | Armored or reinforced options |

| Environmental resistance | Controlled environments | UV, moisture, temperature extremes |

| Installation ease | High | Moderate to low |

| Cost | Lower | Higher |

Selecting the right Bow-type Drop fiber optic cable

Choosing between indoor and outdoor Bow-type Drop fiber optic cable requires a careful assessment of the installation environment, performance requirements, and budget. Indoor cables are optimal for structured cabling inside buildings, including data centers, offices, and residential deployments. They provide flexibility, ease of termination, and compliance with building codes.

Outdoor cables are suitable for aerial, underground, and conduit installations in exposed environments. Their durable construction ensures signal reliability and longevity, reducing maintenance needs and protecting against environmental hazards. For projects spanning both indoor and outdoor segments, dual-rated Bow-type Drop fiber optic cable may offer a cost-effective and convenient solution.

Other buyer considerations include fiber count, connector compatibility, and installation methods, all of which influence performance and long-term network reliability.

Conclusion

In summary, the primary differences between indoor and outdoor Bow-type Drop fiber optic cable lie in their construction, environmental resistance, performance characteristics, and installation requirements. Indoor cables emphasize flexibility, safety, and ease of handling, while outdoor cables focus on durability, protection against environmental hazards, and long-term signal integrity.

By understanding these distinctions, network planners and installers can select the most suitable Bow-type Drop fiber optic cable for each segment of their deployment. Careful selection ensures reliable performance, compliance with safety and environmental standards, and optimized installation costs, ultimately supporting the success of fiber network projects in residential, commercial, and industrial settings.

Address:Zhong'an Road, Puzhuang Town, Suzhou City, Jiangsu Prov., China

Address:Zhong'an Road, Puzhuang Town, Suzhou City, Jiangsu Prov., China Phone:+86-189 1350 1815

Phone:+86-189 1350 1815 Tel:+86-512-66392923

Tel:+86-512-66392923 Fax:+86-512-66383830

Fax:+86-512-66383830 Email:[email protected]

Email:[email protected] Wechat: xiaobin18913501815

Wechat: xiaobin18913501815 whatsapp: +86 18913501815

whatsapp: +86 18913501815

0

0

English

English русский

русский Español

Español Português

Português عربى

عربى