Web Menu

Product Search

Exit Menu

What are the Key Features that Make GJFJB a Reliable Interconnect Cable?

What are the Key Features that Make GJFJB a Reliable Interconnect Cable?

In the intricate architecture of modern data and communication networks, the reliability of the entire system often hinges on the performance of its most fundamental components: the interconnect cables. Among the various options available, the zipcord interconnect fiber optic cable gjfjb has established itself as a cornerstone for numerous indoor and controlled environment applications. Its widespread adoption is not accidental but is a direct result of a deliberate design that addresses the core needs of network installers, system integrators, and end-users.

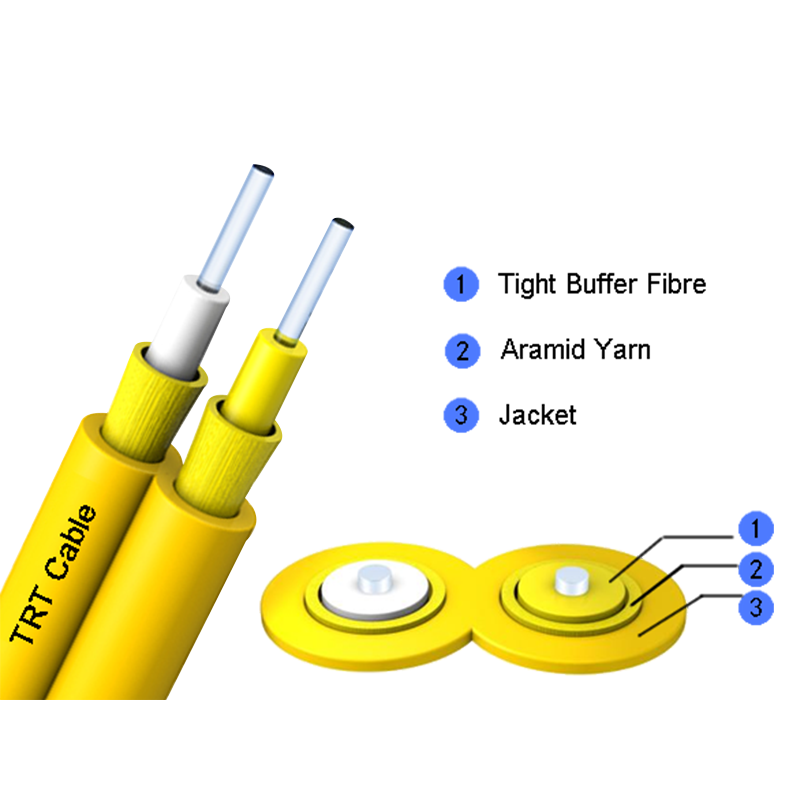

Understanding the Core Construction: A Tight-Buffered Design

The fundamental attribute that defines the zipcord interconnect fiber optic cable gjfjb and forms the bedrock of its reliability is its tight-buffered construction. This design principle is crucial for withstanding the rigors of installation and daily operation in environments where more delicate cables might fail.

The Role of the Primary Buffer Coating

At the heart of every fiber optic cable is the glass fiber itself, which is incredibly thin and fragile. To protect it, an initial layer of protection, known as the primary buffer coating, is applied directly to the cladding. In a tight-buffered design, this primary coating is a rugged, durable plastic material that is applied tightly to the glass fiber. This process creates a robust, solid structure that is typically 900 micrometers in diameter. This design offers significant mechanical advantages. The tight coupling of the buffer to the fiber provides excellent resistance to micro bending and macro bending, which are common causes of signal attenuation (loss). When the cable is bent, pinched, or compressed during installation—for instance, when being routed through tight conduits or bundled with other cables—the tight buffer prevents the glass fiber from experiencing sharp bends that can degrade optical performance. This makes the zipcord interconnect fiber optic cable gjfjb exceptionally tolerant of handling, a critical feature during the often-physical process of network deployment.

Enhanced Mechanical Protection and Handling

Compared to alternative designs like loose-tube cables, which are optimized for outdoor, long-distance runs, the tight-buffered design is inherently more suited for the shorter-distance, high-density, and frequently accessed environments of indoor networks. The individual fibers within a zipcord interconnect fiber optic cable gjfjb are far less susceptible to damage from crushing or impact. This ruggedness translates directly into higher reliability and lower installation failure rates. Installers can have greater confidence when pulling, terminating, and connectorizing these cables, knowing that the core optical fiber is well-protected. This feature is particularly important for interconnect cables, which are often used as patch cords, moved during reconfigurations, or handled directly during maintenance. The robust nature of the tight-buffered fiber ensures that the cable’s optical properties remain stable over time, even in dynamic environments where equipment is added, removed, or repositioned. This stability is a non-negotiable prerequisite for any component claiming to be a reliable part of a network’s infrastructure.

The Zipcord Design: Simplifying Installation and Maintenance

A defining and highly practical feature of this cable type is its zipcord construction. This design, which is simple yet profoundly effective, contributes significantly to the operational reliability and efficiency of network installations.

Ease of Separation and Routing

The term “zipcord” refers to the two individual tight-buffered fiber cables being joined together in a parallel configuration by a thin, mid-span web of jacket material. This design allows installers to easily separate the two fibers for a desired length, much like separating the two sides of a standard electrical zipcord. This feature offers immense practical benefits. When routing cables to different ports on a patch panel or to separate pieces of equipment, the ability to neatly split the duplex cable into two simplex cables provides unparalleled flexibility. It eliminates the need for separate simplex cables, which can become tangled and messy, or the awkward bending and looping of a fixed duplex cable. This not only saves time during the initial installation but also simplifies future moves, adds, and changes (MACs). A cleaner, more organized cable plant is easier to manage, troubleshoot, and maintain, which directly enhances the long-term reliability and serviceability of the network. For buyers and wholesalers supplying to data centers and enterprise networks, this translates to a product that installers prefer due to its labor-saving properties.

Duplex Integrity and Polarity Management

While the ease of separation is a key advantage, the zipcord design also maintains the duplex integrity of the cable where it is needed. For standard duplex communication, where a transmit and receive fiber are required, the two fibers remain bound together for the majority of their length. This built-in pairing ensures that the two fibers necessary for a single link are always kept together, reducing the risk of misidentification or errors during patching. This inherent organization aids in proper polarity management, which is essential for bidirectional communication. By using a standard, consistent color-coding for the two jackets (often aqua for one fiber and orange, or another contrasting color, for the other), the zipcord interconnect fiber optic cable gjfjb provides a visual guide that helps technicians maintain the correct transmit/receive orientation from end to end. This reduces human error, a common source of link failure, thereby bolstering the overall reliability of the network connections it facilitates.

Jacket Material and Fire Safety Compliance

The external jacket of any cable used within a building is not merely a cosmetic feature; it is a critical safety component. The zipcord interconnect fiber optic cable gjfjb is specifically designed with jacket materials that meet stringent fire safety standards, making it a reliable and compliant choice for indoor vertical and horizontal spaces.

Riser-Rated (FR) Jacket Properties

A common and essential rating for the zipcord interconnect fiber optic cable gjfjb is the Riser rating, often designated by the “R” in its specification. Cables with this rating are engineered to resist the propagation of flame from one floor to another through vertical riser shafts. The jacket is manufactured from a flame-retardant material, typically a modified polyethylene or PVC compound, that is self-extinguishing. This means that if the cable is exposed to a fire source, it will not continue to burn once the source is removed. This property is vital for containing a fire and preventing it from spreading via the cable pathways, which can act as chimneys, rapidly carrying fire between floors. The use of a riser rated plenum cable alternative might be considered for different environments, but the riser-rated zipcord interconnect fiber optic cable gjfjb provides a crucial balance of fire safety and cost-effectiveness for many building applications. This compliance with safety codes, such as those outlined by the National Fire Protection Association (NFPA) in the National Electrical Code (NEC), is not optional; it is a mandatory aspect of reliable building infrastructure. Specifying a cable that meets these ratings ensures not only the reliability of the network but also the safety of the building and its occupants.

Low Smoke Generation and Toxicity

In addition to being flame-retardant, the jacket materials used in high-quality zipcord interconnect fiber optic cable gjfjb are often formulated to produce low levels of smoke and toxic halogens when exposed to fire. In a fire event, the greatest danger to life often comes from smoke inhalation and exposure to toxic gases, rather than the flames themselves. Cables that prioritize low smoke and zero halogen (LSZH or LS0H) properties are designed to minimize this risk. While not all GJFJB cables are LSZH, many are available with this option for enhanced safety in enclosed or poorly ventilated areas. The reliability of a cable, therefore, extends beyond mere signal transmission; it encompasses its behavior in failure scenarios. A cable that protects human life and critical equipment by not emitting dense, obstructive smoke or corrosive gases during a fire is fulfilling the highest standard of reliability for infrastructure components. This makes it a responsible choice for network infrastructure in public spaces, transportation hubs, and high-occupancy buildings.

Optical Performance and Environmental Stability

Beyond the physical construction, the intrinsic optical performance of the zipcord interconnect fiber optic cable gjfjb and its stability under various environmental conditions are paramount to its reliability in sustaining communication links.

Consistent Attenuation and Bandwidth

The primary function of any fiber optic cable is to transmit light signals with minimal loss (attenuation) and high fidelity (bandwidth). The zipcord interconnect fiber optic cable gjfjb is typically manufactured to exacting standards to ensure consistent and low attenuation at standard operating wavelengths, such as 850nm, 1300nm for multimode, and 1310nm, 1550nm for single-mode fibers. The combination of the high-quality glass fiber and the protective tight-buffered design works in concert to preserve these optical properties. By preventing stress and bends that can induce signal loss, the cable ensures that the specified attenuation parameters, often measured in decibels per kilometer (dB/km), are maintained not just in a laboratory setting but in a real-world installed state. This consistency is key for network planners who need to accurately calculate power budgets for their links. Knowing that the interconnect cable will perform as specified eliminates a major variable and potential point of failure in the network design, allowing for robust and predictable performance across all connections.

Resistance to Environmental Stressors

While designed for indoor use, the environments within buildings are not always perfectly controlled. Spaces like data centers can have varying temperatures and humidity levels. The materials and construction of the zipcord interconnect fiber optic cable gjfjb provide a degree of resistance to these factors. The tight-buffered design is inherently less susceptible to moisture ingress than loose-tube designs, as there is no air gap for water to travel through. Furthermore, the jacket and buffer materials are selected for their stability across a range of temperatures, preventing them from becoming brittle in cooler conditions or overly soft in warmer conditions. This thermal stability ensures that the cable’s mechanical and optical properties remain constant, preventing performance degradation over time. This resistance to common environmental stressors within its intended operating range contributes significantly to the long-term, set-and-forget reliability that network operators require.

Application-Specific Reliability

The true measure of a component’s reliability is its performance in the specific applications for which it is designed. The features of the zipcord interconnect fiber optic cable gjfjb make it exceptionally reliable in several key use cases.

Data Center Interconnects and Patches

In the high-density, high-availability environment of a data center, reliability is paramount. The zipcord interconnect fiber optic cable gjfjb is a workhorse in these settings, used for server to switch connections, within patch panels, and for interconnecting various pieces of networking equipment. Its rugged tight-buffered construction withstands the constant re-patching and movement that occurs in a dynamic data center. The zipcord design allows for neat and organized routing in crowded cable managers, improving airflow and simplifying tracing for troubleshooting. The fire-safe jacket ensures compliance with the strict codes governing these critical facilities. In this context, the reliability of the zipcord interconnect fiber optic cable gjfjb translates directly to the uptime and operational efficiency of the data center itself.

LAN Backbone and Riser Applications

For the backbone of a Local Area Network (LAN), which connects different floors or wings of a building, a dependable cable is essential. The zipcord interconnect fiber optic cable gjfjb, with its riser-rated jacket, is specifically suited for these vertical runs. Its reliability here is twofold: it provides a stable, low-loss optical pathway for aggregating traffic, and it does so while adhering to fire safety codes for riser spaces. Its ease of installation reduces the time and risk associated with pulling cable through multi-story conduits, while its durability ensures the backbone infrastructure remains sound for years, supporting multiple equipment refresh cycles without needing replacement.

General Equipment Interconnections

Beyond major infrastructure, the zipcord interconnect fiber optic cable gjfjb is also widely used for general equipment interconnections in industrial control systems, medical imaging networks, and broadcast studios. In these settings, the reliability requirement often includes immunity to electromagnetic interference (EMI), a inherent benefit of fiber optics. The physical robustness of the cable protects the link from being damaged by nearby machinery or frequent access by personnel. The consistent performance ensures that sensitive data, whether it’s a medical scan or a live video feed, is transmitted without error or degradation.

Table: Summary of Key Features and Their Reliability Benefits in the zipcord interconnect fiber optic cable gjfjb

| Feature | Description | Primary Reliability Benefit |

|---|---|---|

| Tight-Buffered Construction | A rugged 900µm buffer applied directly to the glass fiber. | Superior protection against bending, crushing, and physical damage, ensuring stable optical performance. |

| Zipcord Design | Two cables joined by a easily separable web. | Simplifies installation and maintenance, reduces human error, and aids in organization for better long-term manageability. |

| Riser-Rated (FR) Jacket | Flame-retardant jacket material that self-extinguishes. | Prevents the spread of fire between floors, ensuring compliance with safety codes and protecting life and property. |

| Consistent Optical Performance | Low attenuation and high bandwidth as per specification. | Provides predictable signal integrity, allowing for accurate network power budgeting and reduced link failures. |

| Environmental Stability | Resistance to temperature variations and moisture. | Maintains performance across the operating range of indoor environments, ensuring long-term reliability. |

The reliability of the zipcord interconnect fiber optic cable gjfjb is not the result of a single, standout feature, but rather the synergistic effect of a well-considered design that addresses the multifaceted challenges of indoor network environments. From the core outward, its tight-buffered construction provides fundamental mechanical protection for the fragile glass fiber. Its practical zipcord design introduces a layer of installation flexibility and operational efficiency that prevents errors and simplifies maintenance. The critical fire-safe jacket ensures that the cable acts as a responsible component of the building’s infrastructure, not a liability. Finally, its consistent optical performance and environmental stability guarantee that the primary function of signal transmission is carried out with unwavering integrity.

Address:Zhong'an Road, Puzhuang Town, Suzhou City, Jiangsu Prov., China

Address:Zhong'an Road, Puzhuang Town, Suzhou City, Jiangsu Prov., China Phone:+86-189 1350 1815

Phone:+86-189 1350 1815 Tel:+86-512-66392923

Tel:+86-512-66392923 Fax:+86-512-66383830

Fax:+86-512-66383830 Email:[email protected]

Email:[email protected] Wechat: xiaobin18913501815

Wechat: xiaobin18913501815 whatsapp: +86 18913501815

whatsapp: +86 18913501815

0

0

English

English русский

русский Español

Español Português

Português عربى

عربى