Web Menu

Product Search

Exit Menu

Performance and Application Analysis of Central Tube Optical Cable

Performance and Application Analysis of Central Tube Optical Cable

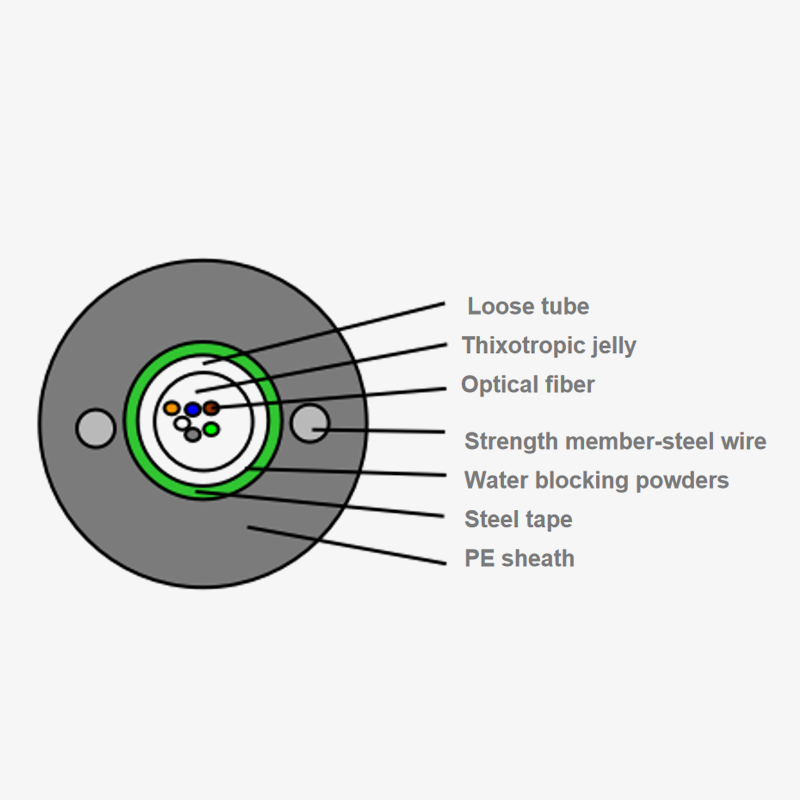

Structural design of central tube optical cable

The central tube optical cable is unique in structure. Its core part is the loose tube of the optical fiber center, in which 2 to 12 cores of single-mode or multi-mode optical fiber are placed. These optical fibers have a certain amount of activity space in the loose tube, and the loose tube is made of high modulus material, with good flexibility and mechanical strength, which can effectively protect the optical fiber from the direct influence of external stress. The loose tube is filled with a paste-like substance. This waterproof compound can not only prevent moisture from invading and damaging the optical fiber, but also buffer the external pressure to a certain extent, providing double protection for the optical fiber. Outside the loose tube, a layer of copolymer coated steel belt is wrapped. This layer of steel belt plays multiple roles, enhancing the overall compressive strength of the optical cable, resisting external extrusion, and ensuring the safety of the internal optical fiber. The steel belt has a certain shielding performance, which can reduce the influence of external electromagnetic interference on the optical fiber signal transmission. In order to further improve the waterproof performance of the optical cable, water-blocking material is added between the steel belt and the loose tube to ensure the compactness and longitudinal water-blocking effect of the optical cable in a humid environment. Two parallel 1.2 mm steel wires are placed on both sides of the steel belt. As the main reinforcement elements, they greatly improve the tensile strength of the optical cable. When laying overhead or over long distances, the steel wires can withstand most of the tension, preventing the optical cable from breaking due to its own weight or external pulling, ensuring the stability of the communication line. The outermost polyethylene outer sheath provides the final protection for the optical cable. It has good weather resistance, wear resistance and chemical stability, and can resist the erosion of ultraviolet rays, rain, wind and sand, and various chemical substances, extending the service life of the optical cable.

Performance advantages of central tube optical cable

Central tube optical cable provides two types of optical fibers, single-mode and multi-mode, to meet different communication needs. Single-mode optical fiber is suitable for long-distance, high-speed data transmission, such as telecommunications backbone networks, long-distance communications and other scenarios. Its low dispersion characteristics can ensure that the signal maintains a good waveform during transmission, reduce signal distortion, and achieve efficient and stable long-distance transmission. Multimode optical fiber is more suitable for short-distance, high-bandwidth applications. It can transmit multiple modes of optical signals at the same time, has a high coupling efficiency, and is convenient for equipment connection and maintenance. Each optical fiber has a specific color code that follows the full color spectrum standard, which enables fast and accurate identification and differentiation of different optical fibers during construction and maintenance. Thanks to its unique structural design, the central tube optical cable has excellent waterproof performance. The paste filling in the loose tube, the water-blocking material between the steel belt and the loose tube, and the polyethylene outer sheath together constitute a complete waterproof system, which effectively prevents moisture from invading the interior of the optical cable from all directions, ensuring that the transmission performance of the optical fiber is not affected by moisture. In terms of compression resistance, the combination of the copolymer coated steel belt and two parallel steel wires gives the optical cable a strong compression resistance, which can withstand large external pressure. Even in complex construction environments or when accidentally squeezed, it can ensure the integrity of the internal optical fiber and maintain normal communication. The polyethylene outer sheath of the central tube optical cable is made of selected materials with excellent physical and chemical properties. It can not only effectively resist the erosion of the external environment, but also maintain good flexibility and mechanical properties under different temperature conditions, ensuring that the optical cable can work normally in various environments. The optical cable strictly controls the process parameters during the production process, and selects high-quality optical fiber materials, so that the optical fiber has the characteristics of low attenuation and low dispersion. The flexible design of the loose tube and the reasonable structural layout enable the optical cable to adapt to various complex terrains and installation environments during the laying process, and can be easily bent to bypass obstacles, reducing the difficulty of construction.

Customization and application of central tube optical cable

The central tube optical cable can be customized according to the specific requirements of customers. Whether in terms of the number of optical fiber cores, optical fiber type, sheath material, or the length of the optical cable, special mechanical performance requirements, etc., it can meet the diverse needs of different users. This customized service enables the central tube optical cable to be widely used in various fields. In the field of communication networks, the central tube optical cable is an important foundation for building the backbone network, metropolitan area network and access network of telecom operators. Its stable performance and high reliability can ensure that a large amount of data is transmitted quickly and accurately between different regions. In the fiber-to-the-home (FTTH) project, the central tube optical cable can be easily laid to the user's home with its good flexibility and easy construction characteristics, providing users with high-speed and stable broadband access services. In terms of dedicated networks, the data transmission of monitoring systems in industries such as electricity, transportation, and petroleum is also inseparable from the central tube optical cable. The working environment of these industries is often complex, and the stability, waterproofness, and pressure resistance of communication lines are extremely high. The central tube optical cable can operate reliably in harsh environments, ensuring the real-time transmission of monitoring data, and providing strong support for the industry's safe production and efficient management.

Address:Zhong'an Road, Puzhuang Town, Suzhou City, Jiangsu Prov., China

Address:Zhong'an Road, Puzhuang Town, Suzhou City, Jiangsu Prov., China Phone:+86-189 1350 1815

Phone:+86-189 1350 1815 Tel:+86-512-66392923

Tel:+86-512-66392923 Fax:+86-512-66383830

Fax:+86-512-66383830 Email:[email protected]

Email:[email protected] Wechat: xiaobin18913501815

Wechat: xiaobin18913501815 whatsapp: +86 18913501815

whatsapp: +86 18913501815

0

0

English

English русский

русский Español

Español Português

Português عربى

عربى