Web Menu

Product Search

Exit Menu

Bow-type drop fiber optic cable: A reliable choice for communication transmission

Bow-type drop fiber optic cable: A reliable choice for communication transmission

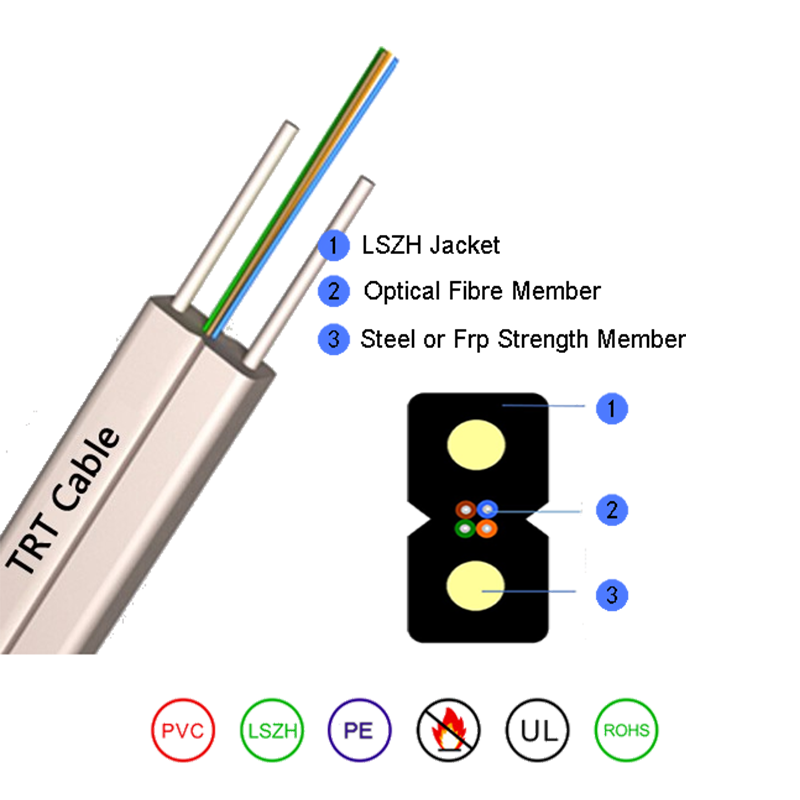

As a key carrier of information transmission, the performance of optical cable directly affects the quality of communication. Among many optical cable products, the internal structure design of bow-type drop fiber optic cable is exquisite. Its core part, the optical fiber unit, is located in the center. The precise setting of this position ensures that the optical fiber can avoid external interference to the greatest extent when transmitting signals, and guarantees the stability and accuracy of signal transmission. The optical fiber unit uses a special low-bend sensitivity optical fiber, which has high bandwidth characteristics and can allow a large amount of data information to pass smoothly and at high speed. On both sides of the optical fiber unit, two parallel fiber reinforced plastic (FRP) reinforcement rods guard the optical fiber. FRP material has the characteristics of high strength and low density. The two parallel FRP reinforcement rods provide good anti-extrusion performance for the optical cable, effectively protect the optical fiber from damage by external pressure, and reduce the overall weight of the optical cable to a certain extent, making the optical cable lighter and easier to install while ensuring performance.

Unique external design facilitates convenient construction

After the internal core structure is completed, the bow-type drop fiber optic cable will be sheathed with black or colored low-smoke zero-halogen (LSZH) material. This sheath material has many advantages. Its low-smoke, halogen-free and flame-retardant properties ensure safety when laid indoors and outdoors. In the event of an emergency such as a fire, the low-smoke zero-halogen sheath can effectively reduce the generation of smoke and the release of toxic gases, reducing the harm to personnel and the environment. The bow-type drop fiber optic cable also adopts a novel groove design. This design is not only for beauty, but more importantly, it improves the convenience of optical cable construction. During installation and maintenance, the groove design makes the optical cable easy to strip and splice. Construction personnel can easily handle the optical cable without the help of complex tools and cumbersome operating procedures, simplifying installation and maintenance work and saving a lot of time and labor costs.

Excellent comprehensive performance shows practical value

From the overall performance point of view, the bow-type drop fiber optic cable has a simple structure, which enables it to reduce costs during the production and manufacturing process, and also facilitates construction personnel to quickly familiarize themselves with and master its characteristics. The advantage of light weight makes the laying process easier, whether it is wiring in a small space or laying over a long distance, it can reduce the difficulty and workload of construction. The strong practicality is reflected in its wide application in various communication scenarios, such as the user introduction section of fiber to the home (FTTH), fiber to the office (FTTO), fiber to the building (FTTB) and other networks, as well as the connection of optical cables between buildings, wiring along walls, ceilings, mezzanines and pipes, etc. In actual applications, the special low bending sensitivity optical fiber of the bow-type drop fiber optic cable can maintain good signal transmission performance in a complex wiring environment, and even if the optical cable is bent to a certain extent, it will not cause a significant impact on the signal transmission. Two parallel FRP reinforcement rods give the optical cable sufficient strength to enable it to withstand certain external forces pulling and squeezing, ensuring stable operation in various harsh environments. The application of low-smoke halogen-free flame-retardant sheath not only ensures safe use, but also conforms to modern environmental protection concepts and contributes to the construction of green communication networks.

Address:Zhong'an Road, Puzhuang Town, Suzhou City, Jiangsu Prov., China

Address:Zhong'an Road, Puzhuang Town, Suzhou City, Jiangsu Prov., China Phone:+86-189 1350 1815

Phone:+86-189 1350 1815 Tel:+86-512-66392923

Tel:+86-512-66392923 Fax:+86-512-66383830

Fax:+86-512-66383830 Email:[email protected]

Email:[email protected] Wechat: xiaobin18913501815

Wechat: xiaobin18913501815 whatsapp: +86 18913501815

whatsapp: +86 18913501815

0

0

English

English русский

русский Español

Español Português

Português عربى

عربى