Web Menu

Product Search

Exit Menu

How does all-dielectric self-supporting aerial optical cable (ADSS) cope with the long-term stability challenges in complex environments?

How does all-dielectric self-supporting aerial optical cable (ADSS) cope with the long-term stability challenges in complex environments?

Due to its unique non-metallic structure and self-supporting design, all-dielectric self-supporting aerial optical cable (ADSS) is widely used in power communication networks, especially suitable for installation in high-voltage transmission line corridors. However, the aerial laying environment poses a severe test to the long-term reliability of optical cables, including ultraviolet radiation, extreme temperature differences, dynamic wind vibration, ice and snow loads, and strong electric field interference. The environmental adaptability design of ADSS optical cable is centered around these challenges, and through the comprehensive application of material selection, structural optimization and protection strategies, it ensures its stable operation under complex working conditions.

In an aerial environment, ultraviolet (UV) radiation is one of the main factors leading to the aging of optical cable sheaths. Long-term exposure to direct sunlight can easily cause molecular chain breakage in ordinary polyethylene (PE) materials, resulting in brittle and cracked sheaths, which in turn affects the mechanical properties and sealing of optical cables. The outer sheath of ADSS optical cable usually adopts high-density polyethylene (HDPE) or tracking-resistant polyethylene (AT-PE), and carbon black or other anti-UV stabilizers are added to the material to effectively absorb and scatter ultraviolet rays and delay the photo-oxidation process. This protection mechanism enables the optical cable to maintain flexibility and impact resistance after long-term outdoor operation, avoiding the increase of optical fiber microbending loss caused by sheath degradation.

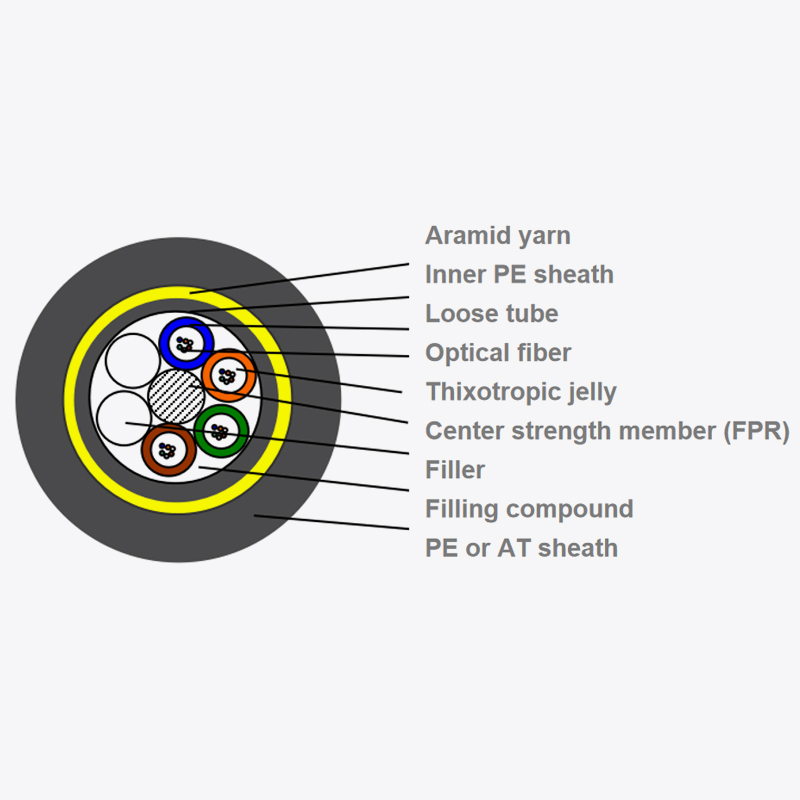

In addition to ultraviolet rays, drastic temperature changes also pose a challenge to the structural stability of optical cables. In areas with large temperature differences between day and night or extreme seasonal climates, optical cable materials will experience repeated thermal expansion and contraction. If improperly designed, it may cause residual stress in the optical fiber and even lead to deterioration of transmission performance. ADSS optical cable copes with this problem by optimizing the excess length design. Its loose-tube layer twisting structure allows the optical fiber to maintain a moderate excess length in the sheath, ensuring that the optical fiber is not affected by external stress within a wide temperature range of -40℃ to 70℃. At the same time, aramid yarn, as a tensile element, has an extremely low thermal expansion coefficient, which enables the optical cable to maintain stable mechanical properties when the temperature fluctuates, avoiding stress concentration caused by material expansion and contraction.

Wind vibration and ice and snow loads are another type of dynamic mechanical stress faced by overhead optical cables. In strong wind environments, optical cables will produce high-frequency vibrations, and long-term effects may cause structural fatigue and even fiber breakage. ADSS optical cables use high-specific-strength aramid yarn as reinforcements, and their excellent tensile and fatigue resistance can effectively resist the impact of wind vibration. The lightweight characteristics of aramid yarn also reduce the overall weight of the optical cable, reduce its swing amplitude under wind force, and thus reduce the impact of wind vibration on the tower and the optical cable body. In areas covered with ice and snow, the sheath material of ADSS optical cables must have sufficient compressive resistance to prevent local deformation caused by ice accumulation. Its structural design usually adopts a circular cross-section to reduce ice and snow adhesion, and the flexibility of the sheath ensures that the transmission performance of the optical fiber can be maintained under ice coverage.

The strong electric field environment of the transmission line corridor puts forward unique electrical performance requirements for ADSS optical cables. Since optical cables are usually installed on the same tower as high-voltage conductors, local discharge may occur on their surface due to electric field induction. Long-term effects will cause electrical corrosion and perforation of the sheath, threatening the life of the optical cable. To this end, the outer sheath of the ADSS optical cable uses a specially formulated anti-tracking material, and reduces the surface electric field strength by optimizing the thickness and dielectric properties. In addition, the surface of the sheath can be treated with hydrophobicity to reduce the accumulation of dirt and moisture, avoid the formation of conductive channels, and thus inhibit corona discharge and arc erosion. This design enables the ADSS optical cable to remain stable for a long time in a strong electric field environment of 110kV or even 500kV, and reliable insulation can be achieved without relying on a metal shielding layer.

The environmental adaptability of the ADSS optical cable is not only reflected in the optimization of a single performance, but also in the systematic balance of the overall design. For example, the UV resistance of the sheath needs to be considered in conjunction with the anti-tracking properties to avoid additives affecting the electrical stability of the material; the tensile strength of the aramid yarn needs to match the bending performance of the optical cable to ensure that it is not easy to break under strong wind conditions, and the construction and laying are not affected by excessive rigidity. This multi-factor collaborative optimization design concept enables the ADSS optical cable to achieve long-term maintenance-free operation in complex environments and become a key infrastructure for power communication networks.

In the future, as the power system's requirements for communication reliability continue to increase, the environmental adaptability design of ADSS optical cables will continue to evolve. The introduction of new composite materials and intelligent monitoring technology may provide a better solution for the long-term stability of optical cables in extreme climates and strong electromagnetic environments. However, no matter how it develops, its core design logic will not change: that is, on the basis of the all-media architecture, through the deep integration of material science and structural mechanics, the optical cable always maintains excellent mechanical and transmission performance in complex environments.

Address:Zhong'an Road, Puzhuang Town, Suzhou City, Jiangsu Prov., China

Address:Zhong'an Road, Puzhuang Town, Suzhou City, Jiangsu Prov., China Phone:+86-189 1350 1815

Phone:+86-189 1350 1815 Tel:+86-512-66392923

Tel:+86-512-66392923 Fax:+86-512-66383830

Fax:+86-512-66383830 Email:[email protected]

Email:[email protected] Wechat: xiaobin18913501815

Wechat: xiaobin18913501815 whatsapp: +86 18913501815

whatsapp: +86 18913501815

0

0

English

English русский

русский Español

Español Português

Português عربى

عربى