Web Menu

Product Search

Exit Menu

How do you properly install and maintain simplex fiber optic cable GJFJ?

How do you properly install and maintain simplex fiber optic cable GJFJ?

Simplex fiber optic cable GJFJ is a single-strand optical fiber cable designed for one-way data transmission. It is widely used in applications where a single communication line is sufficient, such as in medical devices, industrial sensors, and certain telecommunications setups. Proper installation and maintenance are critical to ensuring optimal performance and longevity.

Understanding simplex fiber optic cable GJFJ

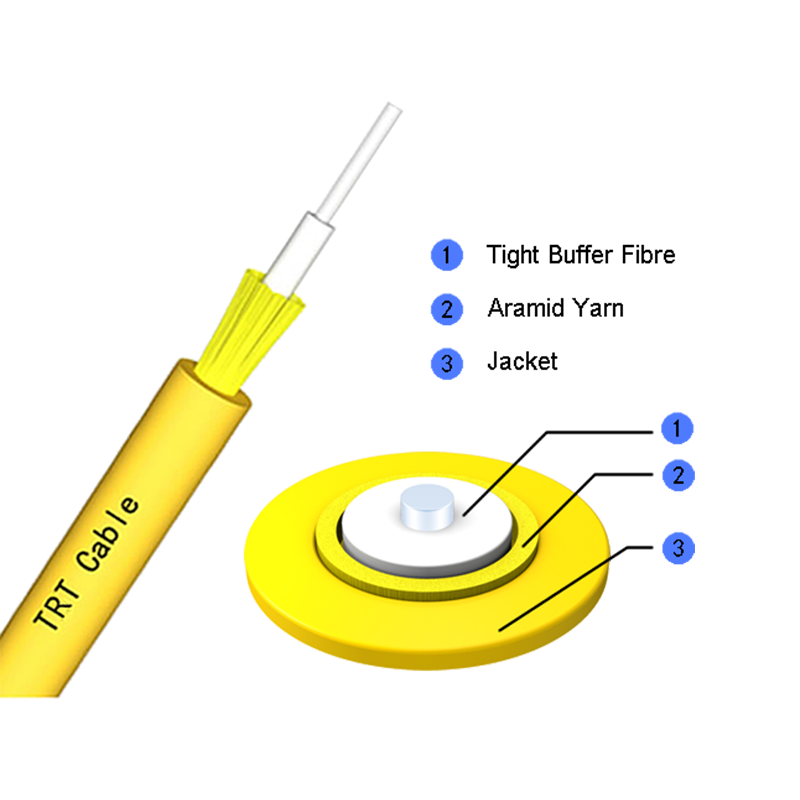

Before installation, it is essential to understand the basic structure and properties of simplex fiber optic cable GJFJ. The cable consists of a single optical fiber core, typically made of glass or plastic, surrounded by protective layers including a buffer coating, strength members, and an outer jacket. The GJFJ designation indicates specific industry-standard construction, ensuring durability and performance in various environments.

Key characteristics of simplex fiber optic cable GJFJ include:

- Single-mode or multimode fiber options.

- High tensile strength due to reinforced layers.

- Resistance to environmental factors such as moisture and temperature fluctuations.

Pre-installation considerations

Proper planning is necessary before installing simplex fiber optic cable GJFJ. This includes assessing the route, ensuring proper tools are available, and verifying compatibility with existing infrastructure.

Important steps before installation:

- Route inspection: Check for potential obstacles, sharp bends, or areas with excessive tension.

- Tool preparation: Ensure availability of fiber cleavers, strippers, splicing equipment, and cleaning supplies.

- Environmental assessment: Avoid areas with extreme temperatures, chemicals, or mechanical stress unless the cable is specifically rated for such conditions.

Installation procedures

Installing simplex fiber optic cable GJFJ requires precision to avoid signal loss or physical damage. The following steps outline the best practices for installation.

1. Cable handling and unspooling

Simplex fiber optic cable GJFJ should be unspooled carefully to prevent kinks or twists. Use a rotating cable spool holder if available. Never exceed the minimum bend radius, which is typically 10 times the cable diameter for long-term installations.

2. Routing and securing the cable

When routing the cable, avoid sharp bends or excessive tension. Use cable clips, conduits, or raceways to secure the simplex fiber optic cable GJFJ in place. Ensure that the cable is not crushed or pinched, especially near connectors.

3. Connector installation and termination

Proper termination is crucial for maintaining signal integrity. Follow these steps:

- Strip the cable jacket carefully without damaging the fiber.

- Clean the fiber with alcohol wipes to remove contaminants.

- Use a precision cleaver to ensure a smooth end face before connector attachment.

- Polish the connector (if required) to minimize insertion loss.

4. Testing and verification

After installation, test the simplex fiber optic cable GJFJ using an optical power meter and light source to verify signal strength and continuity. Record baseline measurements for future maintenance comparisons.

Maintenance best practices

Regular maintenance ensures long-term reliability of simplex fiber optic cable GJFJ. The following practices help prevent performance degradation.

1. Routine inspections

Periodically check for physical damage, such as cracks, bends, or connector contamination. Pay special attention to areas exposed to environmental stress.

2. Cleaning procedures

Dust and dirt can significantly impact performance. Clean connectors using lint-free wipes and isopropyl alcohol. Avoid touching the fiber end faces directly.

3. Storage and handling precautions

When not in use, store simplex fiber optic cable GJFJ in a dry, temperature-controlled environment. Coil the cable loosely to prevent stress on the fiber.

4. Documentation and record-keeping

Maintain logs of installation dates, test results, and any repairs performed. This helps in troubleshooting and predicting future maintenance needs.

Common issues and troubleshooting

Despite proper installation, issues may arise with simplex fiber optic cable GJFJ. Below are common problems and solutions.

| Issue | Possible Cause | Solution |

|---|---|---|

| High insertion loss | Dirty connectors, poor splicing | Clean connectors, re-splice if necessary |

| Intermittent signal | Bent fiber, loose connection | Inspect for bends, secure connections |

| Complete signal loss | Fiber break, connector damage | Replace damaged sections or connectors |

Proper installation and maintenance of simplex fiber optic cable GJFJ are essential for ensuring reliable performance. By following industry best practices in handling, routing, termination, and upkeep, users can maximize the lifespan and efficiency of their fiber optic systems. Regular inspections and adherence to cleaning protocols further reduce the risk of failures. Whether used in industrial, medical, or telecommunications applications, simplex fiber optic cable GJFJ delivers consistent performance when installed and maintained correctly.

Address:Zhong'an Road, Puzhuang Town, Suzhou City, Jiangsu Prov., China

Address:Zhong'an Road, Puzhuang Town, Suzhou City, Jiangsu Prov., China Phone:+86-189 1350 1815

Phone:+86-189 1350 1815 Tel:+86-512-66392923

Tel:+86-512-66392923 Fax:+86-512-66383830

Fax:+86-512-66383830 Email:[email protected]

Email:[email protected] Wechat: xiaobin18913501815

Wechat: xiaobin18913501815 whatsapp: +86 18913501815

whatsapp: +86 18913501815

0

0

English

English русский

русский Español

Español Português

Português عربى

عربى